Finishes

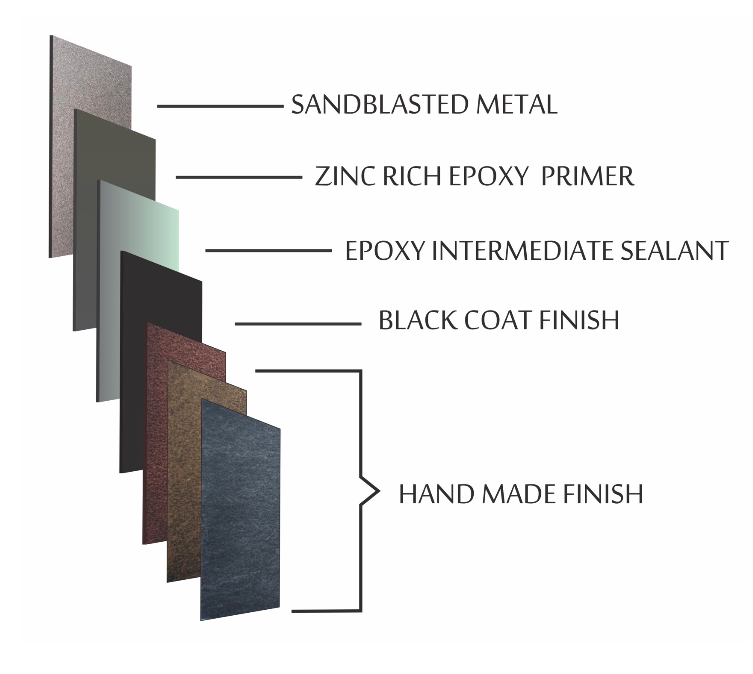

PAINT PROCESS

1.- SANDBLASTING METAL

Surface preparation is paramount for an effective and successful coating application. A substrate that is dirty, greasy, insufficiently textured, or still has old paint can mean the difference between a valuable coating investment and a failure. One of the most effective methods of substrate preparation is abrasive blasting. Abrasive blasting is the process of modifying or cleaning a substrate by blowing abrasive material at high pressure towards its surface with either air or water. The combination of pressure and the grit abrade the surface in a controllable manner. Abrasive blasting (aka grit blasting or sandblasting) is the umbrella term for these processes; individually they are known by the type of material or grit being used for abrasion.

2.- EPOXY ZINC RICH PRIMER

The epoxy zinc-rich primers offer superior long-term protection for steel from corrosion and have excellent adhesive and protective properties. They perform similarly to galvanizing for structural steel surfaces. These primers contain a high percentage of zinc dust, which acts sacrificially when in direct contact with the steel. The zinc salts, which invariably form, fill the pores of the primer sealing off the steel substrate from moisture.

3.- EPOXY PRIMER SEALANT

Epoxy primers are amazing at sealing the zinc rich epoxy primer coat on metal and from allowing moisture or corrosion to creep in. Epoxy primer actually seals out the oxygen from the metal, leaving no chance of rust or corrosion forming on the surface like some cheap spray bomb type primers, with the epoxy primer prepare the surface for apply the paint finish coat.

SPRAY FINISHES

MATT BLACK

WHITE

CHOCOLATE BROWN

HAND MADE FINISHES

LIGHT COPPER

LIGHT BRONZE

LIGTH PEWTTER

MEDIUM COPPER

MEDIUM BRONZE

MEDIUM PEWTTER

DARK COPPER

DARK BRONZE

DARK PEWTTER

WE CAN MATCH RAL COLORS